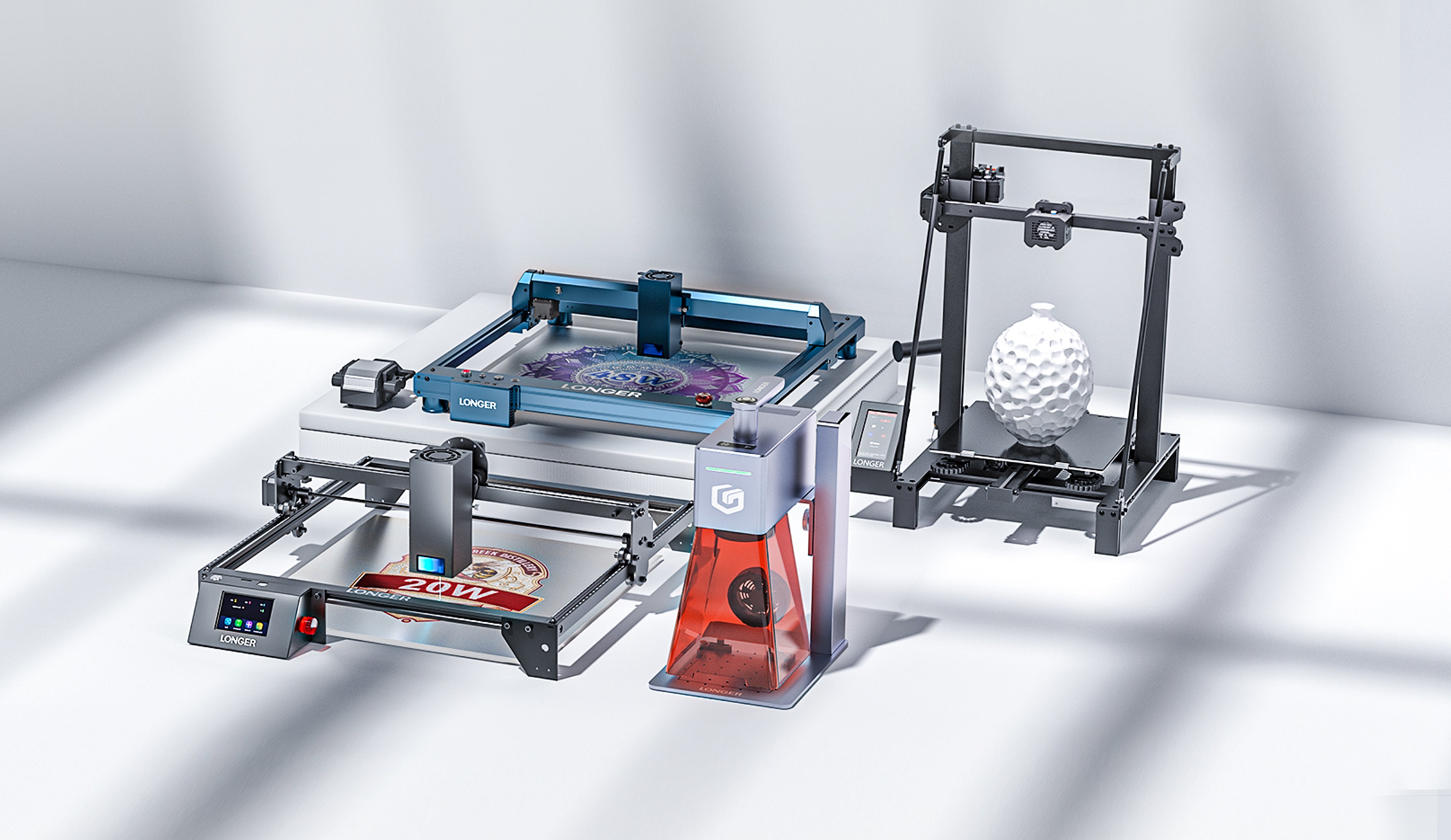

Accessory Guide: Upgrade Smart for Better Results

Honeycomb Panel (Highly Recommended!): Protects base, avoids reflection, improves results.

Air Assist (Highly Recommended!): Removes smoke/debris during engraving, enhances line clarity.

Roller: Enables cylindrical engraving (cups, tubes, etc.)

Extension Rods: Expand engraving area.

Camera: (B1 Series) Allows precise design placement.

IR Laser Head: For metal/ceramic marking.

Smoke Purifier: Improves air quality, protects health.

Back-to-School Bundle Tip: Accessories bought separately are often pricier. Back-to-school bundles offer 25%-42% OFF. Choose a package that includes key items like a honeycomb panel and air pump for best value. For example, the Ray5 20W Pro Max's accessory value exceeds the bundle discount.

This back-to-school season, by evaluating your needs, focusing on key specs, prioritizing safety and ease of use, and grabbing the best bundle deals, you can find a high-value laser engraver that supports your learning, creativity, and entrepreneurship. Take action now and start your laser engraving journey today!