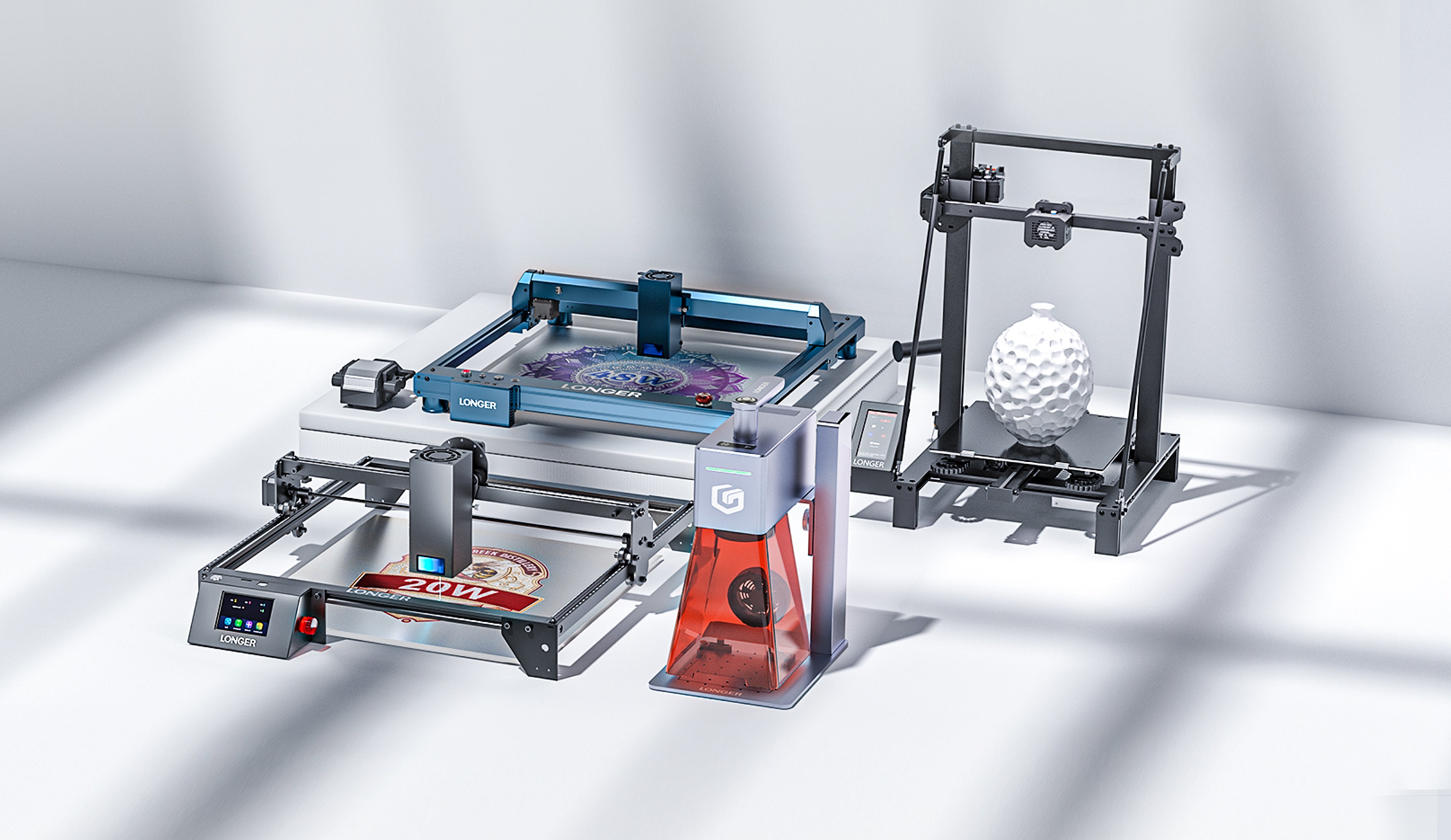

Products

Very simple to use, good laser power ad security features. Small but very precise and with great resolution. It seems more powerfull than it is. Even the support from longer is very good

Ho comprato Longer Ray5 mini pochi giorni fa. All'inizio ha funzionato bene con l'app LaserBurn installata sul mio telefonino Samsung S24 collegandolo al wifi in AP mode. Purtroppo oggi non si collega più perché il telefonino non trova la rete LongerLaser_94F8 che fino ad oggi trovava. Mi potreste aiutare a risolvere questo problema ? Se no sarò costretto a restituire l'incisore.

Come mini laser tutto ok anche per materiali consegna, devo solo capire e provare meglio essendo il primo lncisore laser e sto cercando di capire le varie applicazione per farlo funzionare al meglio delle sue capacità, però intanto mi piace per materiali, assemblato bene insomma non è giocatoloso, se riesco posso divertirmi, c'è da considerare che è il mio primo incisore, sono partito convinto, ma ho capito che devo imparare qualcosa, grazie mille per apparecchio il resto è colpa mia